Page 467 - 日本前田TONE

P. 467

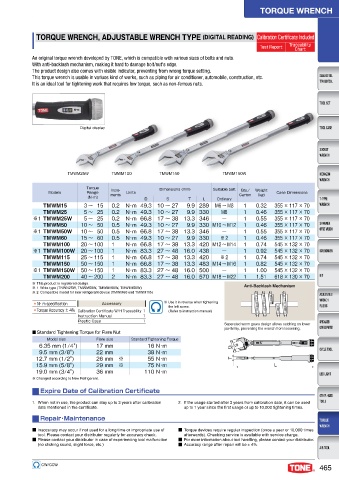

TORQUE WRENCH, ADJUSTABLE WRENCH TYPE (DIGITAL READING) Calibration Certificate Included

Test Report Traceability

Chart

An original torque wrench developed by TONE, which is compatible with various sizes of bolts and nuts.

With anti-backlash mechanism, making it hard to damage bolt/nut's edge.

The product design also comes with visible indicator, preventing from wrong torque setting.

This torque wrench is usable in variuos kind of works, such as piping for air conditioner, automobile, construction, etc.

It is an ideal tool for tightening work that requires low torque, such as non-ferrous nuts.

Digital display

TMWM25W TMWM100 TMWM150 TMWM150W

Torque Dimensions (mm) Suitable bolt

Incre-

Qty./

Models Range ments Units Carton Weight Case Dimensions

(kg)

(N・m) D S T L Ordinary

TMWM15 3~ 15 0.2 N・m 49.3 10 ~ 27 9.9 289 M6 ~ M8 1 0.32 355 × 117 × 70

TMWM25 5~ 25 0.2 N・m 49.3 10 ~ 27 9.9 330 M8 1 0.46 355 × 117 × 70

※1 TMWM25W 5~ 25 0.2 N・m 66.8 17 ~ 38 13.3 346 ― 1 0.55 355 × 117 × 70

TMWM50 10 ~ 50 0.5 N・m 49.3 10 ~ 27 9.9 330 M10 ~ M12 1 0.46 355 × 117 × 70

※1 TMWM50W 10 ~ 50 0.5 N・m 66.8 17 ~ 38 13.3 346 ― 1 0.55 355 × 117 × 70

TMWM60 15 ~ 60 0.5 N・m 49.3 10 ~ 27 9.9 330 ※2 1 0.46 355 × 117 × 70

TMWM100 20 ~ 100 1 N・m 66.8 17 ~ 38 13.3 420 M12 ~ M14 1 0.74 545 × 132 × 70

※1 TMWM100W 20 ~ 100 1 N・m 83.3 27 ~ 48 16.0 438 ― 1 0.92 545 × 132 × 70

TMWM115 25 ~ 115 1 N・m 66.8 17 ~ 38 13.3 420 ※2 1 0.74 545 × 132 × 70

TMWM150 50 ~ 150 1 N・m 66.8 17 ~ 38 13.3 483 M14 ~ M16 1 0.82 545 × 132 × 70

※1 TMWM150W 50 ~ 150 1 N・m 83.3 27 ~ 48 16.0 500 ― 1 1.00 545 × 132 × 70

TMWM200 40 ~ 200 2 N・m 83.3 27 ~ 48 16.0 570 M18 ~ M22 1 1.51 618 × 130 × 70

※ This product is registered design.

※ 1 Wide type (TNWN25W, TMWM50W, TMWM100W, TMWM150W) Anti-Backlash Mechanism

※ 2 Compatible model for new refrigerant device (TMWM60 and TMWM115)

● N・ m specification Accessory ※ Use it in reverse when tightening

the left screw.

● Torque Accuracy ± 4% Calibration Certificate W/H Traceability 1 (Refer to instruction manual)

Instruction Manual 1

Plastic Case 1

Seperated worm gears design allows catching on lower

jaw firmly, preventing the wrench from loosening.

■ Standard Tightening Torque for Flare Nut

Model size Flare size Standard Tightening Torque

6.35 mm (1/4") 17 mm 16 N・m

9.5 mm (3/8") 22 mm 38 N・m

12.7 mm (1/2") 26 mm ※ 55 N・m

15.9 mm (5/8") 29 mm ※ 75 N・m

19.0 mm (3/4") 36 mm 110 N・m

※ Changed according to New Refrigerent.

Expire Date of Calibration Certificate

1. When not in use, the product can stay up to 3 years after calibration 2. If the usage started after 3 years from calibration date, it can be used

date mentioned in the certificate. up to 1 year since the first usage or up to 10,000 tightening times.

Repair・Maintenance

■ Inaccuracy may occur if not used for a long time or impropriate use of ■ Torque devices require regular inspection (once a year or 10,000 times

tool. Please contact your distributor regularly for accuracy check. afterwards). Checking service is available with service charge.

■ Please contact your distributor in case of experiencing tool malfunction ■ For more information about tool handling, please contact your distributor.

(no clicking sound, slight force, etc.) ■ Accuracy range after repair will be ± 4%.

465